Predictive Maintenance

Read morePredictive Maintenance utilizes advanced data analytics to forecast when equipment will require maintenance, allowing for timely interventions before breakdowns occur. This approach optimizes machinery performance, reduces energy consumption, and minimizes waste, leading to significant cost savings and a lower environmental footprint. By ensuring equipment operates efficiently and lasts longer, Predictive Maintenance plays a crucial role in promoting sustainability and operational excellence.

Structural Health Monitoring

Read moreStructural Health Monitoring (SHM) leverages sensors and data analytics to continuously assess the condition of structures like buildings and bridges. This proactive method detects early signs of potential issues, enabling timely maintenance and repairs. SHM enhances infrastructure safety, extends lifespan, and promotes sustainability by minimizing the need for extensive repairs. It's a key technology for ensuring a safer, more sustainable built environment.

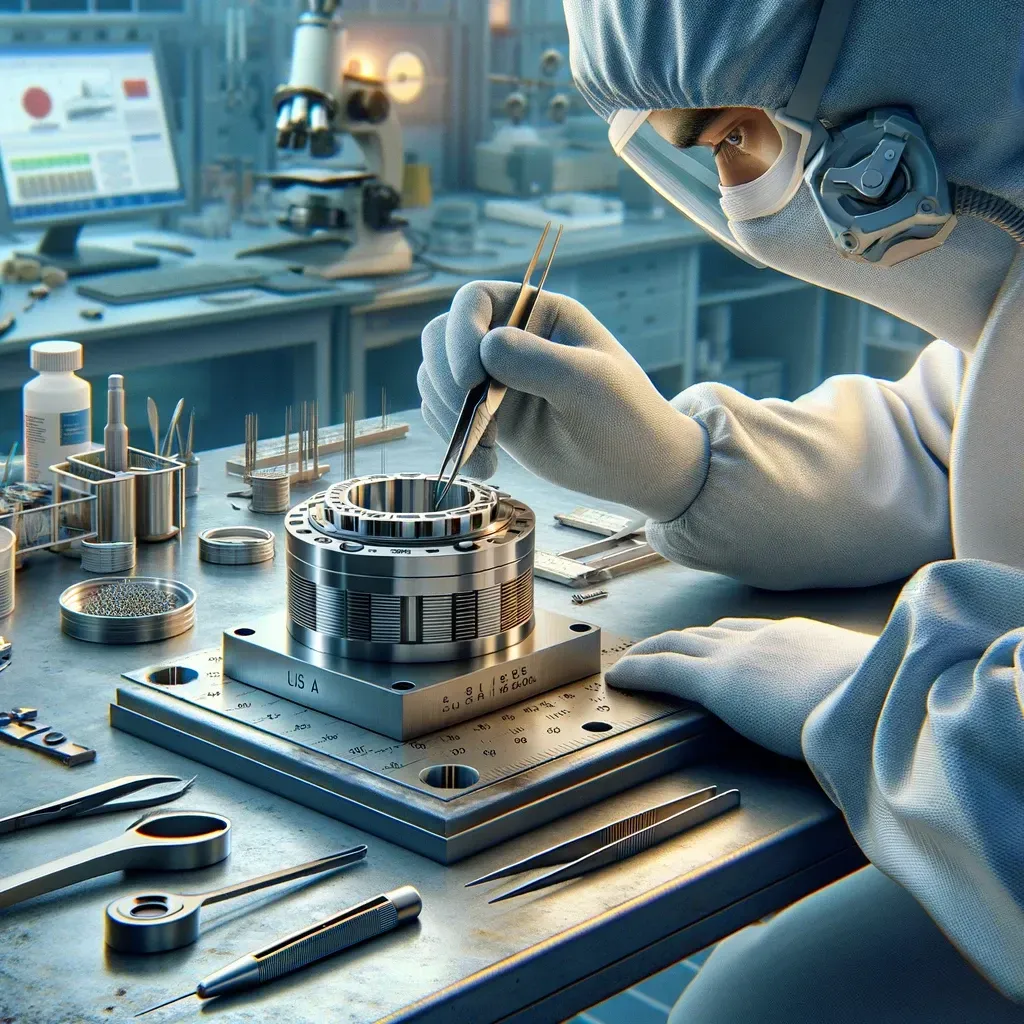

Bonding Services

Read moreStrain gauge bonding services involve attaching strain gauges to materials or structures to measure strain (deformation) under loads. This precise task is critical for ensuring accurate and reliable measurements in various applications, from engineering research and structural analysis to manufacturing and more.

Root Cause Analysis

Read moreRoot Cause Analysis (RCA) is a methodical approach used to identify the underlying reasons for problems or incidents. By focusing on the root causes rather than just addressing the immediate symptoms, RCA enables organizations to implement long-term solutions that prevent recurrence. This process enhances operational efficiency, improves safety, and reduces costs by eliminating the need for repeated fixes. RCA is a cornerstone for continuous improvement in any sector.

Non Destructive Testing

Read moreNon-Destructive Testing (NDT) is a crucial technique used to evaluate the properties and integrity of materials and structures without causing any damage. It enables the detection of defects and inconsistencies, ensuring safety and reliability in various industries, from aerospace to construction, without compromising the operational utility of the inspected item. NDT plays a vital role in preventive maintenance, quality control, and safety assurance.

© 2024 Strain 2 Data bv, All rights reserved. Privacy policy, code of conduct